Vikas Pump is an eminent company engaged in designing, manufacturing, and offering a comprehensive Centrifugal Pump range. As a leading Centrifugal Pump Manufacturers in India, we believe in innovation and delivering excellence that helps us retain the existing customers while attracting new ones. Our experts have eyes for detail, and their strict professionalism and dedication have made us one of the best Industrial Pump Manufacturers in Saharanpur, Uttar Pradesh. Our philosophy and focus on maximizing client satisfaction have helped us expand the reach, product portfolio, and clientele over those years. Being the leading RO Plant and Sewage Treatment Plant Manufacturers in India, we deal in premium quality pumps like Monoblock Pump, Submersible Pumps, Stainless Steel Tank, SS Tank, Package Drinking Water Plant and much more.

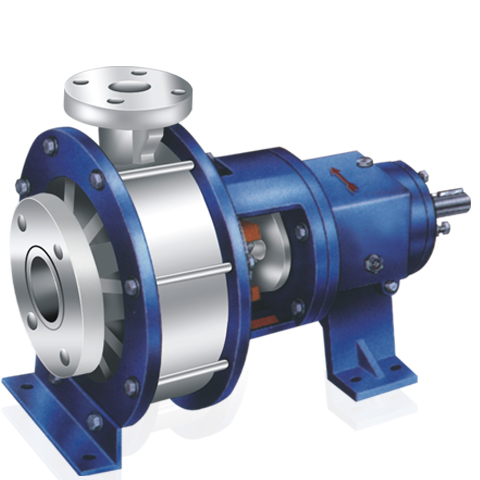

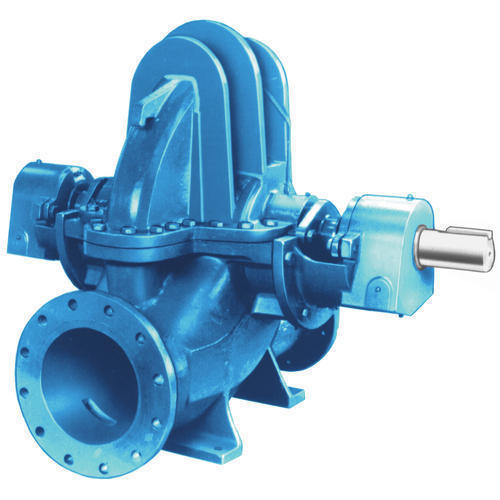

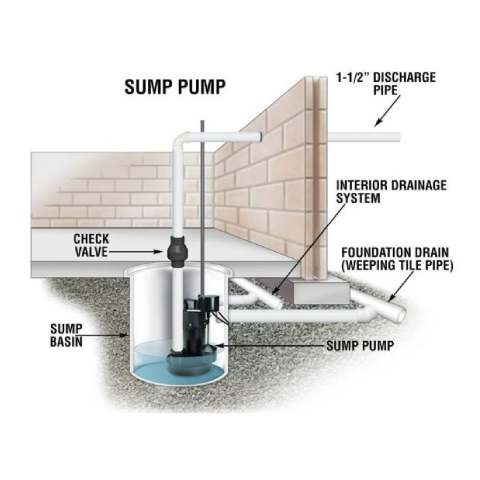

Being the prominent Centrifugal Pumps Manufacturers in India, we promise to offer premium quality, round-the-clock customer support, and prompt delivery as committed has helped us stay ahead of the curve, despite the competition in the domain. We offer two types of Centrifugal pump - Vertical Centrifugal pump and Horizontal Centrifugal pump, These are highly innovative and suitable for multiple applications. Whether you need, Industrial Chain, Steel Tank, or Industrial Conveyor, Mixed flow Pump Manufacturers, Vertical Mixed flow Pump Manufacturers, Split casing pump Manufacturers, End suction Pump Manufacturers, Process Pump Manufacturers, Sludge Pump Manufacturers, Mud Pump Manufacturers, vertical sump pump Manufacturers, Vertical high Pressure Pump Manufacturers, we have the best solution in our inventory to meet your diverse demands which make us a prominent Gear Pump Manufacturers in India.

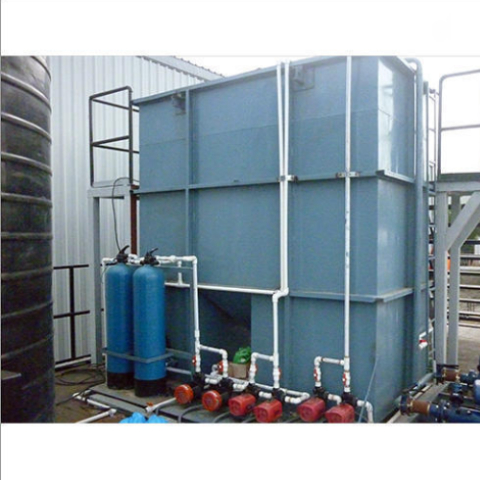

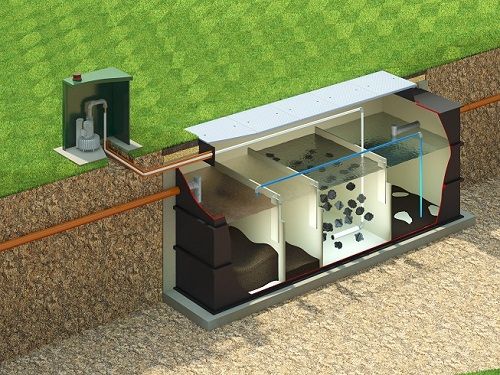

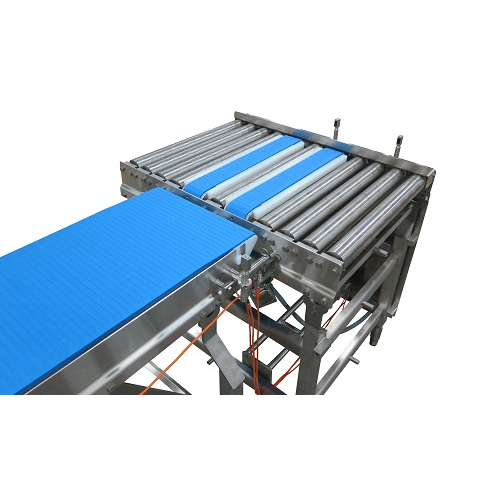

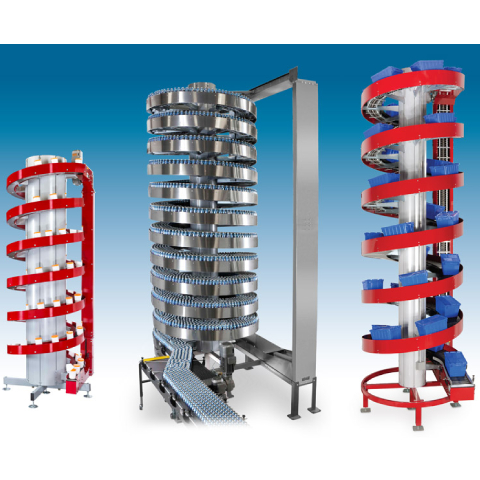

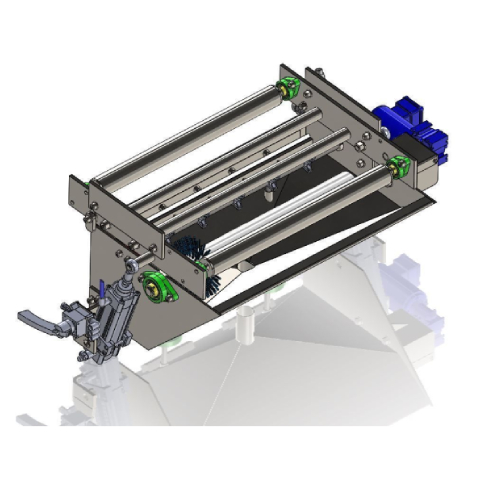

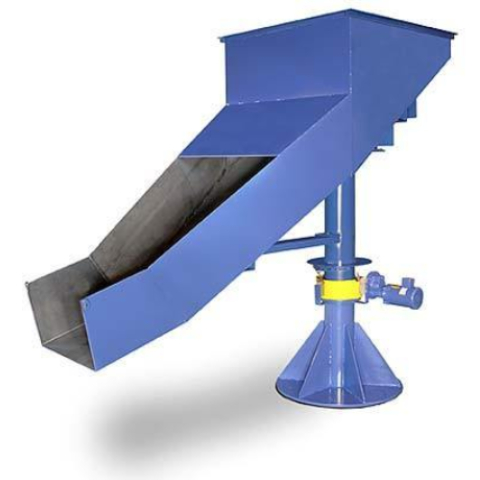

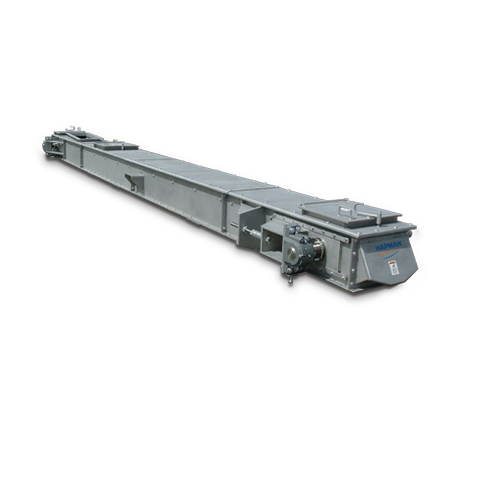

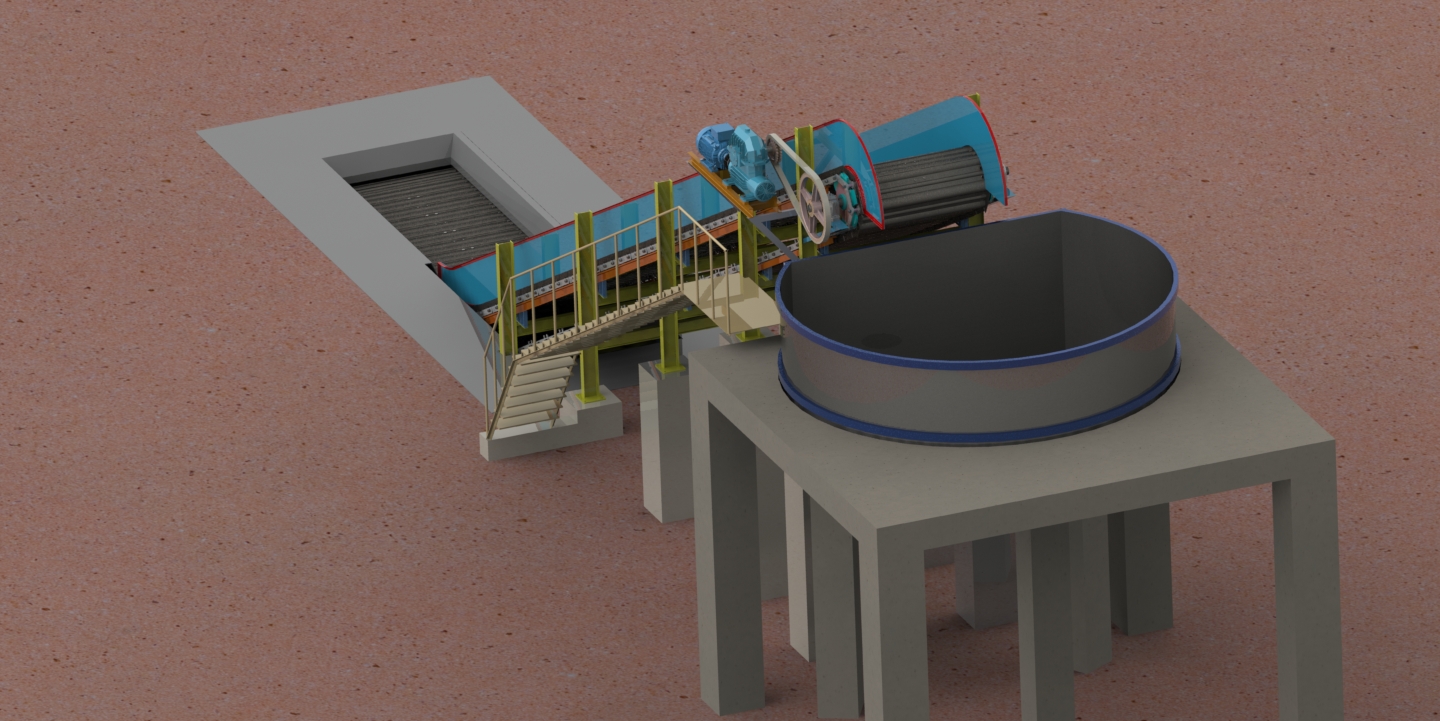

We have modern tools and experienced manpower to understand your demands and deliver the best Pumps For ETP accordingly. The quality of our products reflects the expertise of our company and has made us one of the eminent Belt Conveyor Exporters or Slat Conveyor Manufacturers and Self Priming Pump Suppliers in India. Our STP Plant Manufacturers is demanded in the industry for their excellent functionality and supreme quality. Call us or drop your enquiry to know more.

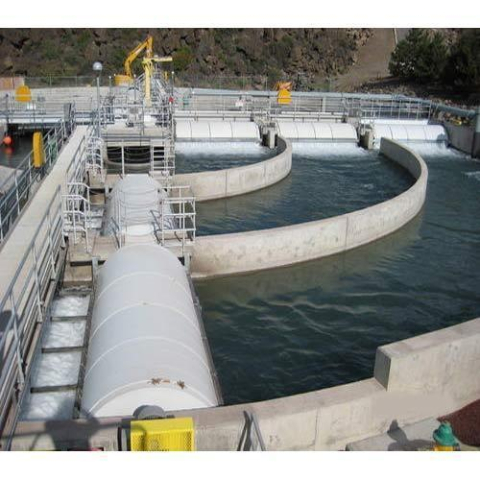

Read MoreIf you are looking Industrial Package Drinking Water Plant and Sewage Treatment Plant Manufacturers that offer a wide range of Water Treatment Plants that can meet domestic, commercial and industrial water cleaning needs, we have got you covered. Our products are as per the industry standards and known for their advancement and superior performance. Check our product portfolio and make your choice as per the need of your industry. We also offer custom-made solutions to cater to your diverse demands without letting you down.

Are you are looking for Stainless Steel Tank Manufacturers that deals in SS Tank, Transfer Conveyors, Bulk Material Handling System, Cement Conveyor, Food Handling Conveyor, Steel Tank, Industrial Chain or Chemical Storage Tank, we are the one-stop you can reach. All our offered products are customized to your preferences and available in different specifications. We have a broad range that you can explore and order with us accordingly.

We are the one-stop Centrifugal Pump Manufacturers in India, where you can find a broad range of Industrial Pump like Monoblock Pump, Submersible Pump for different processes and industries. Our offered range of Stainless Steel Centrifugal Pump and Self Priming Centrifugal Pump are highly demanded in the market for its sturdy and long lasting performance. Each product has its characteristics and known for their premium quality and unmatched performance. We have set strict quality grounds for our range and make sure every unit of ours pass it before reaching you. You can check our complete line of products on the website and order with us as per your requirements.

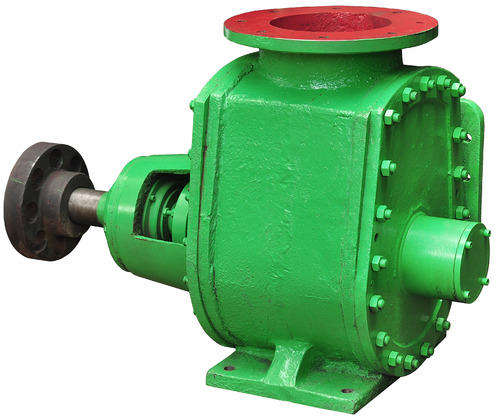

Being the leading Centrifugal Pump manufacturers in India, we deals in wide range of Industrial Pump. The pumping operation of centrifugal pump & industrial pump converts kinetic energy to potential energy or we can call it as centrifugal force. Fluid enters the liquid because of the rotating impeller which creates a vacuum, then it goes to the volute casing this whole process can be done by the help of a rotating shaft which get energy from the electric motor the pump & motor is to be coupled by the help of different coupling as per the customer requirement, pumps have three main components what is the capacity pump has to handle, what will be the total dynamic head (tdh) or we can say it as velocity or pressure discharge, the shaft will connect with bearing housing which rotates with the help of bearing it is complete Industrial-pumps. As a leading Gear Pump Manufacturers in India, we bring a vast collection of Industrial Pump in different specifications.

Never made us wait and delivered the product on time. Experienced team, premium quality and paramount support, we got everything we have asked for. Highly recommended company.

At the time of purchase, we were quite nervous, but they have won our faith and we are truly impressed with the quality and their after-sale support.

Their prices are extremely budget-friendly. We got the value for money and would recommend their name to all.

Copyright © 2026 Vikas Pump | All Rights Reserved. Website Designed & SEO By Webclick® Digital Pvt. Ltd. Website Designing Company India